Safety Equipment Sect

Thornhill Armament Sect

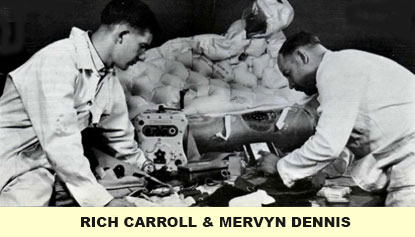

Thornhill Photo Gallery

Takeover from RAF 1955

New Sarum Air Base Thornhill Air Base

Thornhill Air Base Air Force Home Page

Air Force Home Page Site Home Page

Site Home Page

The Safety Equippers by Warrant Officer W. Hayes

Extracted by ORAFS from the November 1968 Ndege

Safety Equippers? Oh yes, they're those funny little blokes who are always trying to pinch our flying clothing." Ask a question about the other man's job in the average crew-room, and that's the sort of answer you're likely to get; a grain of truth embedded in a foundation of apparent indifference.

Safety Equippers? Oh yes, they're those funny little blokes who are always trying to pinch our flying clothing." Ask a question about the other man's job in the average crew-room, and that's the sort of answer you're likely to get; a grain of truth embedded in a foundation of apparent indifference.

As with so many support services, the Safety Equipment Section rarely sees the glare of publicity. The work goes quietly on—without attracting a great deal of attention. One could perhaps speculate that this is the ultimate measure of success, in the sense that if nothing untoward happens, then the job has been well done. We deal in routine, painstaking prevention rather than in dramatic cures. Yet if the dramatic does happen, the work of the Safety Equipment Section Invariably lessens the effect.

Safety Equipment has been an Indispensable part of the aviation scene since the First World War Shortly after the Introduction of the parachute came the introduction of the associated trade groups; the packers and fabric workers.

Dealing at first with the packing, fitting and maintenance of parachutes and harnesses, their scope increased with the growth of aviation. The limitations of merely landing the unfortunate aviator safely were soon realized, and provision had to be made for his subsequent survival in a number of hostile environments.

Thus was equipment devised to sustain him in desert, jungle, Arctic or mountainous conditions; to keep him afloat and kicking on the high seas; and to assist his escape and evasion in enemy-held territories. Aviation's limitations on weight and space resulted in the use of specialist survival kits, designed for a given set of conditions, and containing an ideal balance of food, water and equipment.

Thus was equipment devised to sustain him in desert, jungle, Arctic or mountainous conditions; to keep him afloat and kicking on the high seas; and to assist his escape and evasion in enemy-held territories. Aviation's limitations on weight and space resulted in the use of specialist survival kits, designed for a given set of conditions, and containing an ideal balance of food, water and equipment.

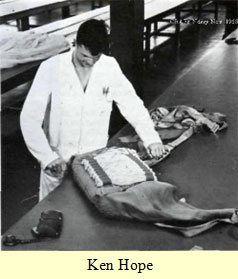

From the early parachute-packing days, the Safety Equipment worker's responsibilities have grown to such an extent that he now finds himself dealing with ejection seats, harnesses, dinghies, Mae Wests, parachutes, survival and ration packs—and all of their associated equipment. He is also responsible for fitting and maintaining a huge variety of flying clothing and personal equipment.

The whole range of the Safety Equipment inventory is carefully designed for the job in hand, and requires painstaking regular servicing since the failure of any single Item could mean the difference of life or death to the user.

The Safety Equipment Sections of the RRAF have developed along with the increased potential and complexity of the aircraft. As each new technical advance produces new equipment, new skills are developed to ensure a long and efficient life for each item. Much of the Section's work is routine and repetitive; all parachutes, for example, are repacked automatically every two months whether they have left the Section in that time or not. The task demands a minute inspection for damage or deterioration, followed by repairs where necessary. The canopies are then hung in a temperature-controlled, ventilated room before further inspections and repacking. The packing process takes from one to three hours, depending on the parachute type, and the whole operation is undertaken about 3,000 times per year between the two Stations.

The Safety Equipment Sections of the RRAF have developed along with the increased potential and complexity of the aircraft. As each new technical advance produces new equipment, new skills are developed to ensure a long and efficient life for each item. Much of the Section's work is routine and repetitive; all parachutes, for example, are repacked automatically every two months whether they have left the Section in that time or not. The task demands a minute inspection for damage or deterioration, followed by repairs where necessary. The canopies are then hung in a temperature-controlled, ventilated room before further inspections and repacking. The packing process takes from one to three hours, depending on the parachute type, and the whole operation is undertaken about 3,000 times per year between the two Stations.

Similar periodic servicing is the general rule for dinghies, survival packs and flying clothing. So when "the funny little bloke' tries to pinch your oxygen mask, he has normally got a very good reason for doing so!

Apart from regular preventive maintenance on normal equipment, a certain amount of specialized work is undertaken for other sections. The fabric workers are constantly engaged in repairing and maintaining a wide variety of items, ranging from tarpaulins and vehicle seat covers to Dakota control surfaces. The scope also extends to fibre-glass these days; radomes, aerial covers and fuselage panels are all repaired by the Safety Equipment Section.

We also have an interest in research and development from time to time. A recent requirement for a small, cheap, disposable supply parachute was satisfied when the Section designed and manufactured a hessian 'chute which is now in operational use. This item differs from standard parachute design in the sense that the pack cover remains with the aircraft and is not lost.

The personal qualities and level of knowledge required of a Safety Equipment worker equate with those demanded by most specialized technical trades, but above all there is a need for absolute concentration at all times. As the name implies, we are concerned primarily with Safety in everything we do. So should the day come when you, the pilot need to bang out; or you, the troops in the bush, need a supply drop, remember that the ultimate success of the exercise depends on the diligence and patience of the Safety Equipment worker. And when he comes round collecting your equipment for servicing, don't argue—give! After all, the survival he's working towards may be your own.